Select delivery location Usually ships within 7 to 8 days. Need a gift sooner Send an Amazon Gift Card instantly by email or SMS. In turn these polymers were solubilized with various concentrations of ammonium hydroxide and utilised in the surfactant-free emulsion polymerization of butyl methacrylate using persulfate initiators, which also stabilized the polymer particles with observed no coagulation, with solid contents as high as 40%. Engineering & Transportation Engineering Buy new: 87.08 List Price: 141.95 Save: 54.87 (39) 3.99 delivery January 3 - 9. For those working in industry, coupling theory with everyday practice can be difficult. Chemistry and Technology of Emulsion Polymerisation 2e provides a practical and intuitive explanation of emulsion polymerization, in combination with both conventional and controlled radical polymerization. Topology is a unique dimension for macromolecular engineering, which has continuously spurred the creativity in synthetic chemistry to explore the boundary of the possible topology and architecture adopted by polymers. Emulsion polymerisation is a technologically and commercially. The vinyl-terminated oligomers were in turn utilised as chain transfer agents, with no further purification, for the formation of diblock copolymers with butyl and methyl methacrylate which constitutes the emulsifier via sulfur-free reversible addition–fragmentation chain transfer polymerisation (SF-RAFT). Chemistry and Technology of Emulsion Polymerisation. An emulsion polymer is prepared by polymerisation of a dispersion of monomer in a liquid, resulting in a colloidal dispersion of solid polymer in that liquid, and they are used extensively in the paints, paper & paperboard, textiles, packaging and adhesives & sealants industries.

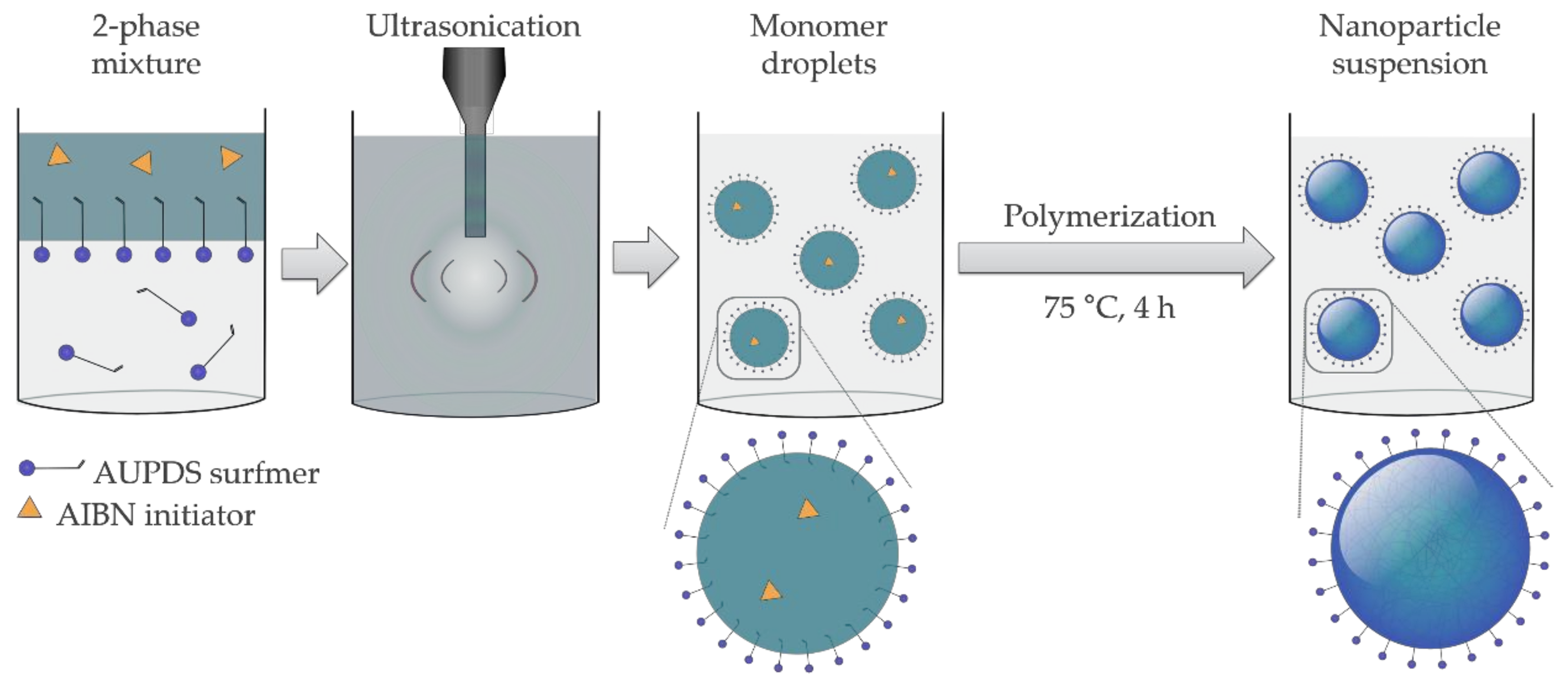

For those working in industry, coupling theory with everyday practice can be difficult. Among them, Pickering emulsion polymerization is of particular interest due to its non-additive organic surfactants, environmentally friendly nature, and high emulsion stability.

#Chemistry and technology of emulsion polymerisation free#

Moreover, the effects of the inherently heterogeneous nature of emulsion polymerization on the mechanism of reversible addition-fragmentation transfer polymerization and the nano-object morphology are examined, and efficient agitation and adequate solubility of the core-forming monomer in water are identified as the most crucial factors for the fabrication of nonspherical nano-objects.ĭispersion polymerization emulsifier-free emulsion polymerization morphological transition nucleation self-assembly.Statistical copolymers of methacrylic acid and methyl methacrylate were synthesised via free radical catalytic chain transfer polymerisation (CCTP) in emulsion to form a hydrophilic emulsifier/surfactant. Inverse emulsion polymerization is an effective manufacturing technology for producing high-performance liquid thickeners. a 'Chemistry and Technology of Emulsion Polymerisation 2e provides a practical and intuitive explanation of emulsion polymerization, in combination with both conventional and controlled radical polymerization.

The present study compares dispersion polymerization with emulsifier-free emulsion polymerization in terms of nucleation mechanism, polymerization kinetics, and disappearance behavior of the macrochain transfer agent, gel permeation chromatograms curves of the obtained block copolymer as well as the structural and morphological differences between the produced nano-objects on the basis of published data. in VDC emulsion polymerization, 25:723 Free-radical styrene polymerization, general chemistry of, 23:381 Free-radical thermal cracking mechanism.

Although the preparation of nano-objects by emulsifier-free controlled/living radical emulsion polymerization has drawn much attention, the morphologies of these formed objects are difficult to predict and to reproduce because of the much more complex nucleation mechanisms of emulsion polymerization compared to only one self-assembling nucleation mechanism of controlled radical dispersion polymerization.

0 kommentar(er)

0 kommentar(er)